Data-informed structural steel integrity

This site had high levels of salinity in the washdown water which reduced the longevity of structural steel and coatings. Risk was understood through quantitative data collection to allow prioritization of maintenance work.

Challenges:

- High salinity washdown water = corrosion of structural steel

ICE impact:

- Created a standard visual inspection proforma for steel in the process plant

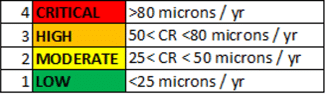

- Collected quantitative corrosion data (coupons, UT measurements, exposure data)

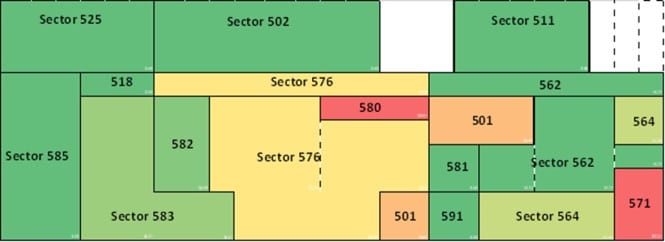

- Created a corrosion risk map for tracking and predicting risk

- Updated the coating specification to match the risk type

- Carried out annual audit inspections to track risk and optimize repair